CO2SupCut2

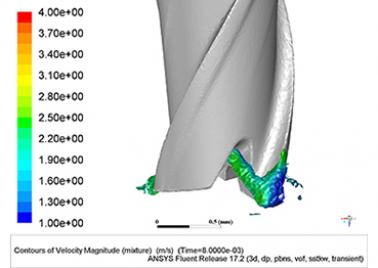

This project develops a machining process using supercritical CO₂ combined with minimum quantity lubrication (MQL). Here, the MQL flow rate is only 0.5 to 2 mL/min, compared to several tens in conventional methods.

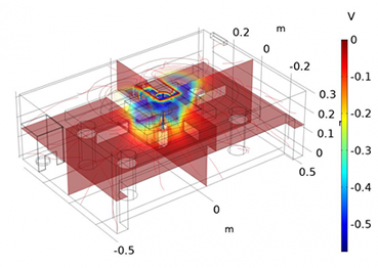

Active Corrosion Control

With the support of Innosuisse, the project team was able to develop a technology that strongly reduces corrosion by an active control of the pH-values based on ionic release prediction and pH adjustment using different ion-exchange resin (suited to absorb anion/cations) and o

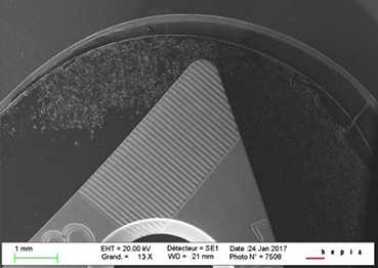

Intrinsic cooling of high performance micro cutting tool ICO-CUT

Development of a high performance hard metal microendmill with central cooling

Eskenazi SA is a Geneva-based company specialized in the manufacture of cutting tools for precision mechanics.

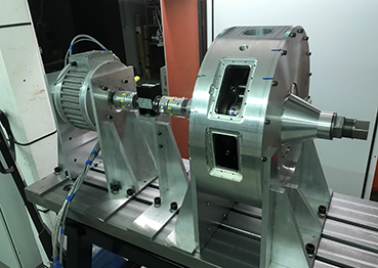

SMART Machine

Project CTI: Intelligent management of consumables and wear parts in wire EDM.

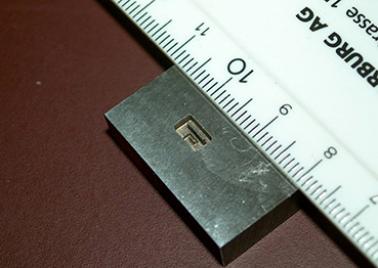

LEMM Light-EDM-Micro-Milling

A refined machine dedicated to micro-milling by electrical discharge machining.

- 1 of 2

- ››