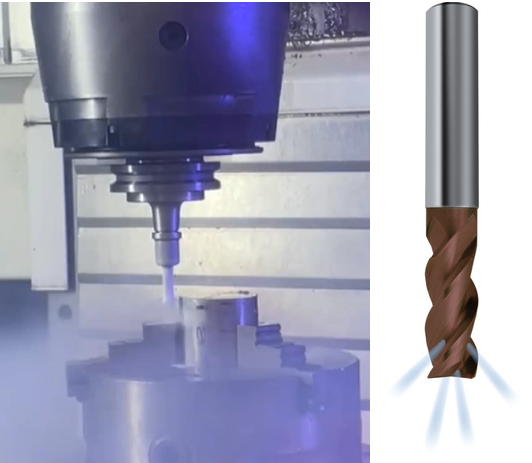

This project develops a machining process using supercritical CO₂ combined with minimum quantity lubrication (MQL). Here, the MQL flow rate is only 0.5 to 2 mL/min, compared to several tens in conventional methods. Supercritical CO₂, a state between liquid and gas, is maintained above 73 bar and 31°C to remain supercritical.

We instrument the entire chain, from CO₂ generation to the cutting edge. Pressure and temperature are continuously monitored to understand the evolution of scCO₂. Numerical simulations (CFD with ANSYS) model the CO₂ flow inside the tool. They help identify critical heat losses and pressure drops.

Machining with scCO₂ and MQL shows improved heat removal. The surface finish of the workpieces is better than with traditional methods. Cutting forces were reduced by 28.5%, due to better thermal control of the cutting zone. Tool life was increased by 20%.

scCO₂ combined with MQL reduces both thermal and mechanical wear of tools.

It improves productivity while consuming less lubricant. The process is cleaner and more sustainable than conventional cutting oils. The results highlight the need to develop dedicated equipment to maintain optimal conditions.

The project received financial support from Innosuisse.

Project partner(s)

Project leader - team

Markus Thurneysen

(HEPIA),

Georg Wälder (HEPIA)

,

Patrick Haas

(HEPIA),

Agim Adilji

(HEPIA),

Mathieu Hageli

(HEPIA),

Ivan Coupy

(HEPIA),

Baptiste Gousset (HEPIA)

,

Alexandre Bourbon (HEPIA)