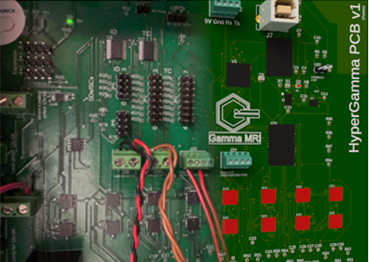

A major advance of the Gamma-MRI project was the complete redesign and integration of the electronics and software. Previously, the prototype relied on a heterogeneous assortment of commercial equipment and disparate control programs, making it complex, inefficient, and costly to use. To address this, the HEPIA team developed a tailored in-house solution: a single printed circuit board (PCB) designed specifically for Gamma-MRI that serves as the control hub for all hardware, eliminating superfluous devices and reducing both complexity and cost.

This PCB now handles a wide range of critical functions: regulation of the magnet environment, oven heating, protective cooling of the magnet, management of pumps and heaters, safety interlocks, TTL signals, laser cooling, and water-temperature monitoring. Coupled with software developed in-house in C#/.NET, it unifies experimental control and supervision into a coherent system, ensuring precise and reliable operation of the prototype while minimizing potential points of failure.

The integrated system drives virtually all functions of the Gamma-MRI prototype, including the laser controller and the detector chain via the CAEN DT5700, enabling real-time measurement, monitoring, and recording of all experimental data. By removing redundant components and centralizing control, the prototype has become a modular, streamlined, and cost-optimized platform, paving the way for new developments and preclinical applications.

Project partner(s)

Project leader - team

Stavroula Pallada

(HEPIA),

Anastasios Kanellakopoulos

(HEPIA),

Ashley Cooper

(HEPIA),

Quentin Rogliardo

(HEPIA),

Anastasia Patsouli

,

Christian Doimo