The Swiss clay industry produces around 350,000 tonnes of clay products every year. This makes it a strong industry, creating jobs and perpetuating a wealth of know-how. However, the latest energy crisis has had a major impact on the industry as a whole, as it depends on imported natural gas to fuel its industrial kilns for firing bricks. For several months now, this industry has been experiencing a steady rise in the price of gas purchased from its suppliers, who are unable to commit to fixed prices given the volatility of the market and the uncertainties linked to the political situation of the main European suppliers. This rise in gas prices has had a direct impact on the selling price of clay products. Manufacturers have had to announce substantial increases to their customers. This situation is encouraging the import of cheaper foreign construction products, and is seriously jeopardising the business of brickmakers, who have already had to implement urgent restructuring measures (temporary plant closures, redundancies).

The aim of this project is to support TFL (Tuileries Fribourg & Lausanne SA), a producer of clay bricks in Crissier (VD), in a more environmentally-friendly approach by offering an alternative solution with bricks that do not undergo a firing process, namely raw clay bricks.

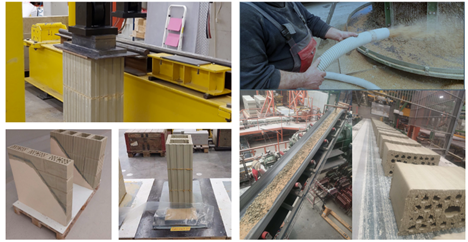

The bricks are manufactured by extrusion, using a moulding machine. The firing stage increases the bricks' mechanical strength and resistance to water (liquid and ambient humidity). The issue is therefore whether the bricks can be used as they are, without firing and without any change to their composition, or whether they need to be modified.

The key strengths of this project are therefore

To achieve this, we had to

Pictures: TFL

Pictures: HEPIA

Project partner(s)

Project leader - team

Abdelkrim Bennani

(HEPIA),

Grégoire Aguettant (HEPIA)

,

Florian Fazio

(HEPIA)