Radon-222 (222Rn) is a radioactive noble gas that occurs naturally in the Earth's crust. Through diffusion, it can be found in the air we breathe. Excessive concentrations in enclosed spaces pose a real health risk.

In Switzerland, radon is considered the main source of exposure to ionising radiation (3.3 mSv/year/person) and is thought to be responsible for 10% of lung cancer cases in Europe, making it the second leading cause after smoking.

Figure: average contribution to the dose in mSv/year per inhabitant in Switzerland, with a total of 6 mSv.

However, due to its inert nature, the danger does not come directly from radon itself, but from its decay products (218Po, 214Pb, 214Bi and 214Po). As it decays, radon produces other lighter but still radioactive elements, which then interact with aerosols in the air due to their chemical nature. It is these radioelements attached to aerosols that are dangerous, because once inhaled, they remain in the lungs and cause significant cellular damage as they decay and produce internal radiation.

In collaboration with BAQ Sàrl, we have designed an innovative air purifier to filter air contaminated by 222Rn decay products. This system features a suction device that generates an air flow directed towards filters.

Initially, in order to find the ideal filter for 222Rn particles, a method was developed to measure a retention factor F. A 200-liters hermetic chamber containing a high concentration of 222Rn (550 kBq/m3) was designed. The contaminated air circulates through a 3D-printed mechanical system, into which a series of identical filters are placed. After exposure, the filters are analyzed using a surface contamination probe to assess their level of radioactivity. The data obtained is then adjusted using a function based on the solution of Bateman's differential equations, which estimates the respective contributions of the first three descendants of 222Rn. This method has been used to test various types of filters commonly used in building ventilation systems, including models from the G4 and F7 ranges.

The next step in the project focused on evaluating the filtration performance of the prototype defeloped jointly by BAQ Sàrl and HEPIA, in a full-scale 23 m³ test room. This purification system has an ionizer that helps aerosols agglomerate, making it easier for the filters to catch them. To intensify contamination, aerosols were artificially introduced into the room using a particle generator. With an average ²²²Rn activity of 1000 Bq/m³, the effective dose reached up to 12 µSv/h. By activating the filtration system in this way, we were able to reduce this dose by a factor of 8, from 12 to 1.5 µSv/h.

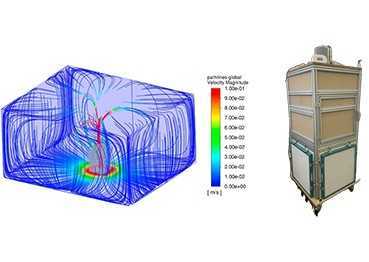

In parallel with the experimental measurements, CFD simulations are being carried out by the Fluid Mechanics and Aerodynamics research group to model the filters used in the experimental device and calculate their retention capacity for aerosols of different sizes, ranging from 10 to 1000 nm.

Picture: CFD simulation and photo of the prototype used to reduce the dose.

Project partner(s)

Project leader - team

Stavroula Pallada

(HEPIA),

Gilles Triscone (HEPIA)

,

Agim Adilji

(HEPIA),

Christophe Balistreri

(HEPIA),

Hugo Corcelle

(HEPIA),

Anastasios Kanellakopoulos

(HEPIA),

Quentin Rogliardo

(HEPIA)